Machine Tools

Precision solutions that boost performance, accuracy, and uptime.

Machine Tools

Precision solutions that boost performance, accuracy, and uptime.

Make the Most of Your Machine Tools.

Machine tools are only as effective as their installation. Even minor misalignments or vibrations can lead to poor tolerances, wasted materials, and unexpected downtime. That’s why UNISORB® delivers precision-engineered solutions built to maximize accuracy, eliminate vibration, and keep your high-performance tools running at their full potential. Whether you’re setting a lathe, grinder, or mill, we help you get more life, more reliability, and more productivity from every machine.

Products for Machine Tools

Our proven products provide the solid foundation your high-precision machine tools need for peak performance.

FIXATORS®

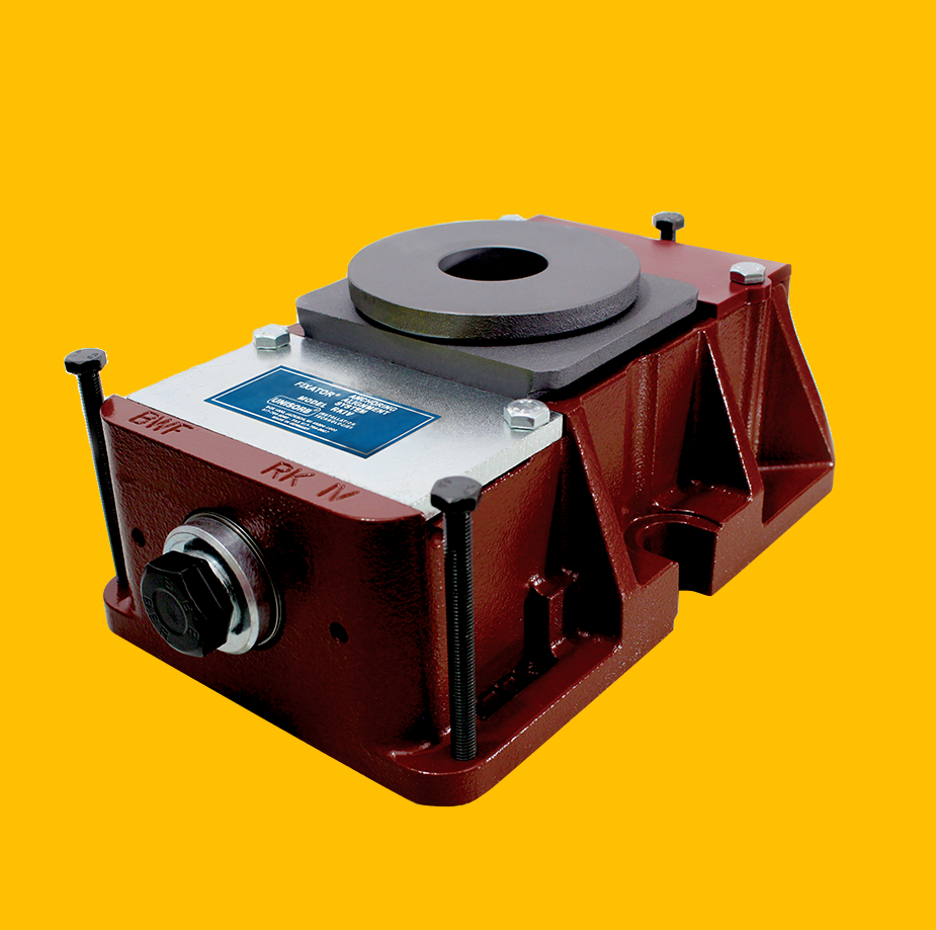

RK FIXATOR®

Achieve unparalleled support-critical anchoring and alignment with effortless micro-level adjustments for lasting precision and minimal downtime.

S FIXATOR®

Features vertical bolt adjustments for precise above-level leveling in floor plates and layout tables, built with a high-density cast iron housing and sealed, low-friction mechanism.

Epoxy Grouts

Standard V-100® Epoxy Grout

Perfect for grouting machine bases, setting anchor bolts, or repairing foundations, it’s designed for high impact resistance and fast curing.

Bulk Pour V-100®

Engineered for deep pours up to 8 inches, this heavy-duty three-component flowable grout, self-levels, and rapidly gains high strength to resist severe impact.

WTF-E V-100® (3 part kit)

Built for high-load applications, this grout delivers impressive compressive strength and robust resistance to temperature, humidity, chemicals, and acids.

Cementitious Grouts

V-1® Premium Non-Shrink Grout

A high-flow, cement-based solution that rapidly builds exceptional compressive strength for heavy-load applications where traditional grouts fall short.

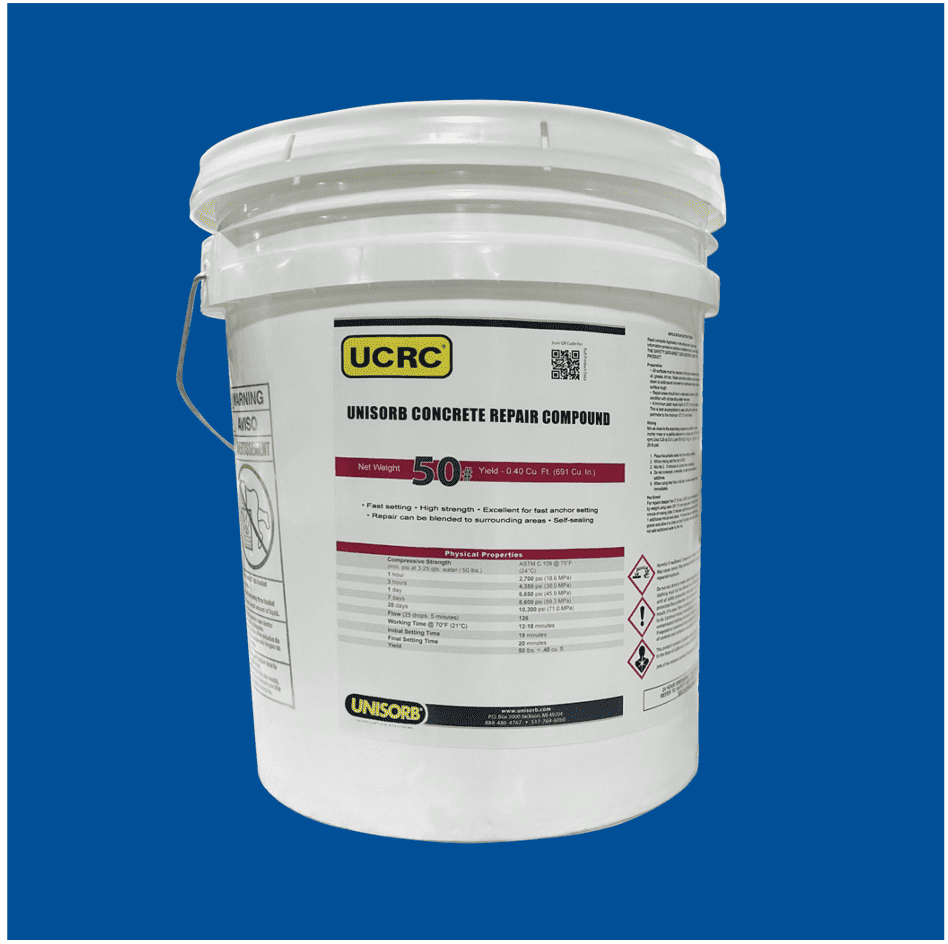

UNISORB® Conrete Repair Compound (UCRC) and UCRC Extended Set

Industrial-grade, precision-formulated concrete repair compound with a durable gray powder blend, engineered for strong adhesion, fast curing, and long-lasting structural restoration in demanding environments.

Anchoring

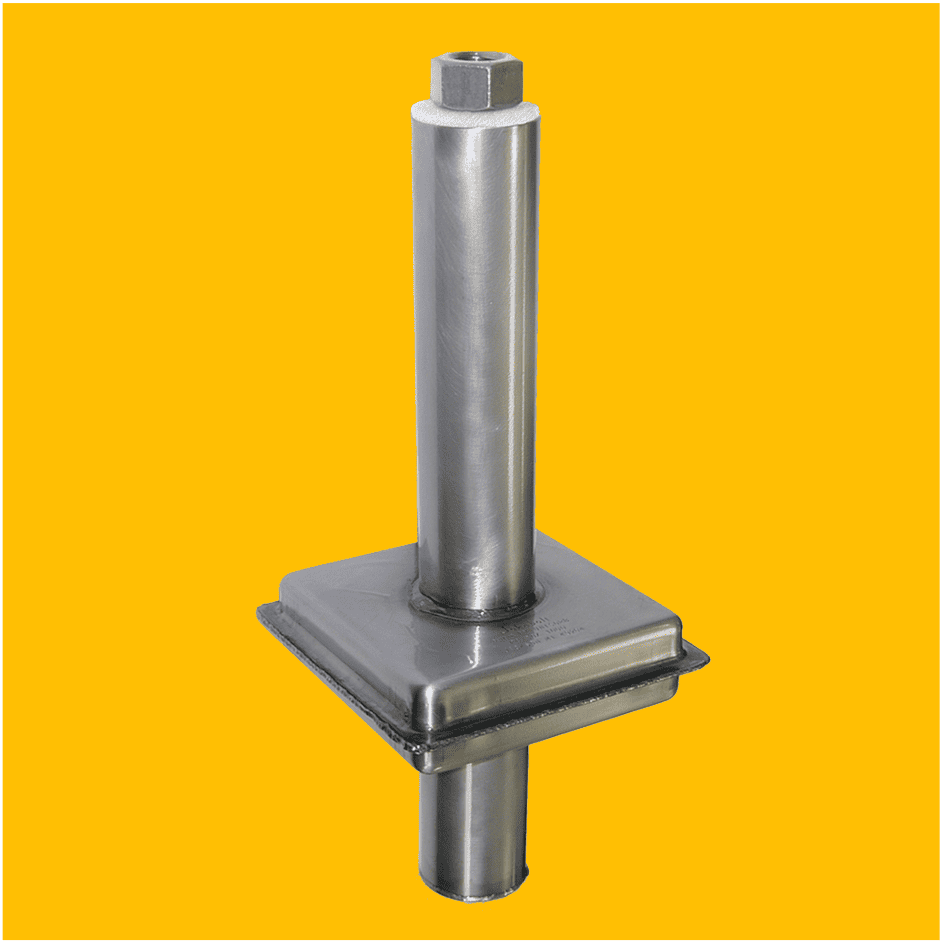

VECTOR® Bolts

Forged from premium steel with a unique embed feature design that maximizes grout contact and converts loads for superior pull-out strength.

Heavy Duty JAKEBOLTS®

High-strength, all-steel anchors with adjustable studs and a centering bushing deliver cost-effective, reliable foundation support.

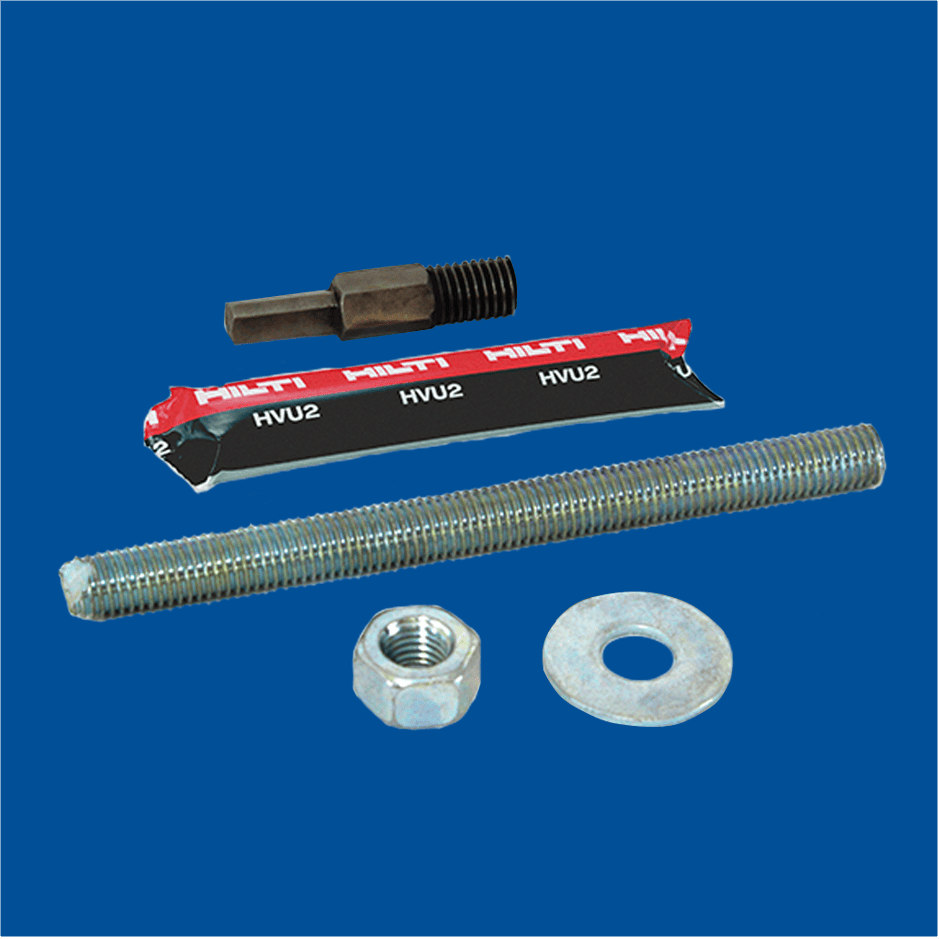

Capsule Anchor System

Secure heavy-duty anchoring with high-strength adhesive for threaded rods or inserts, installed easily with a standard hammer drill.

Foundation Isolation Materials

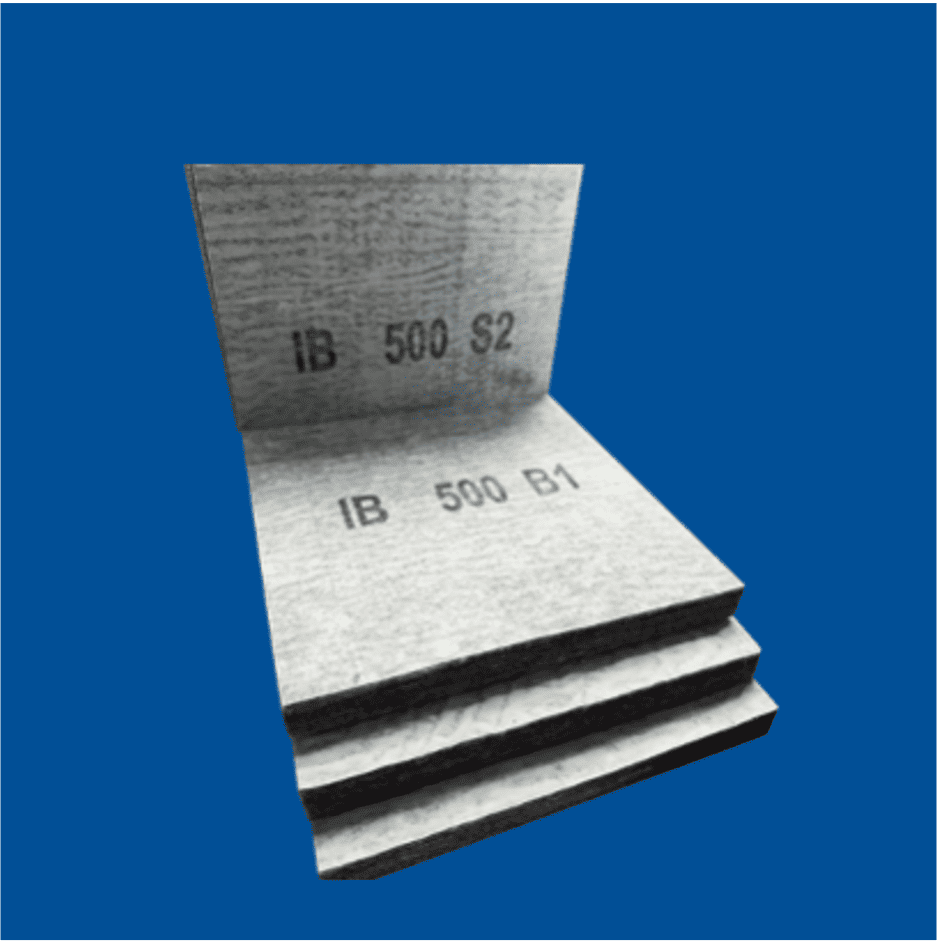

IB-500™ Inertia Block Isolation Materials

Simplify installation with a high-performance foundation isolation system, featuring an 8-19 Hz natural frequency, a concrete inertia block for stability, and engineered damping for superior vibration control in industrial applications.

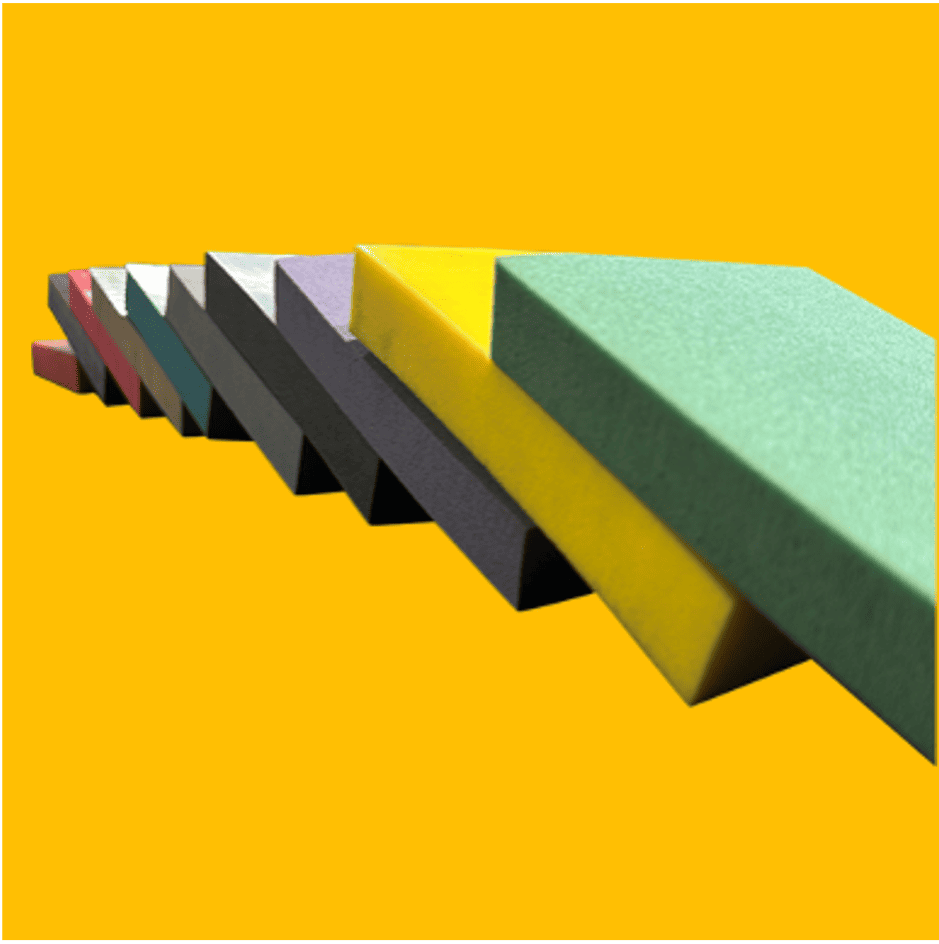

Regufoam® VibrationPlus

(12 variants)

Maximize vibration isolation with engineered polyurethane foam pads, delivering a 6-15 Hz natural frequency range, long-lasting durability, easy installation, and superior damping for industrial foundations. (12 variations)

RT Low Frequency Isolation Block

Reduce vibration interference with high-load natural rubber isolation blocks, engineered for precision applications with a controlled 4.5-5 Hz natural frequency, superior damping, and effective isolation for sensitive equipment and large vibration sources.

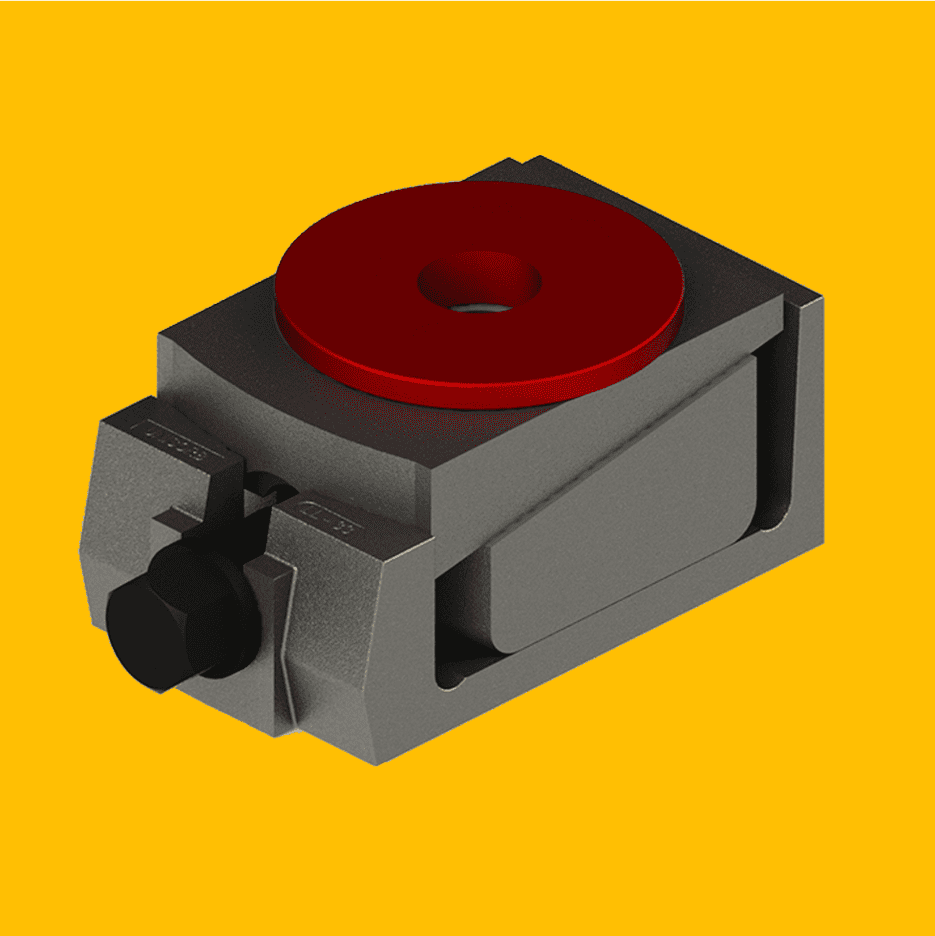

ST Spring Isolator

Eliminate environmental vibrations with high-performance spring isolators, delivering a stable 2-3 Hz natural frequency, superior load capacity, and pre-loaded construction for seamless installation and long-term precision equipment protection.

LEV-L-INE® Machinery Mounts

LEV-L-INE®

Ensure precise, adjustable leveling and secure support with durable mounts engineered to counteract uneven floor distortion. (Available in three sizes.)

LEVEL-RITE® Mounts

LEVEL-RITE® Mounts & Hollow Base Mounting Kit (3 sizes)

Designed for the hollow bases of knee mills, these mounts deliver precise leveling, vibration control, and proper stability. (Available in three sizes.)

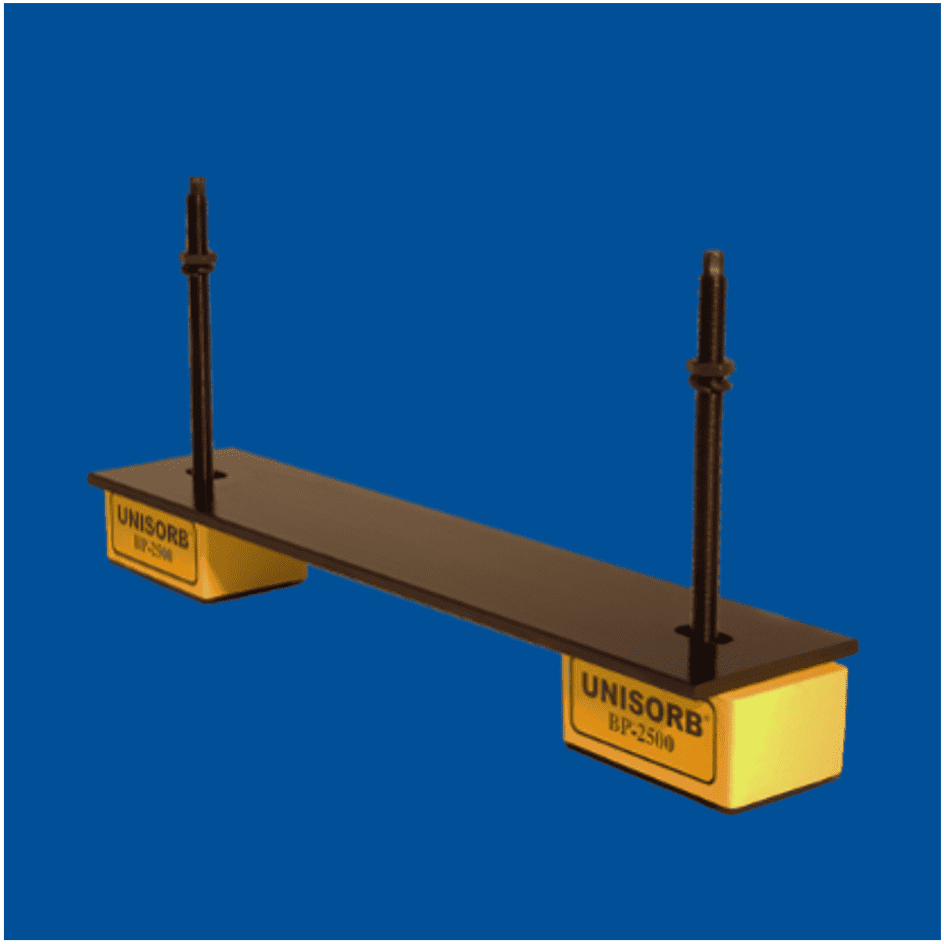

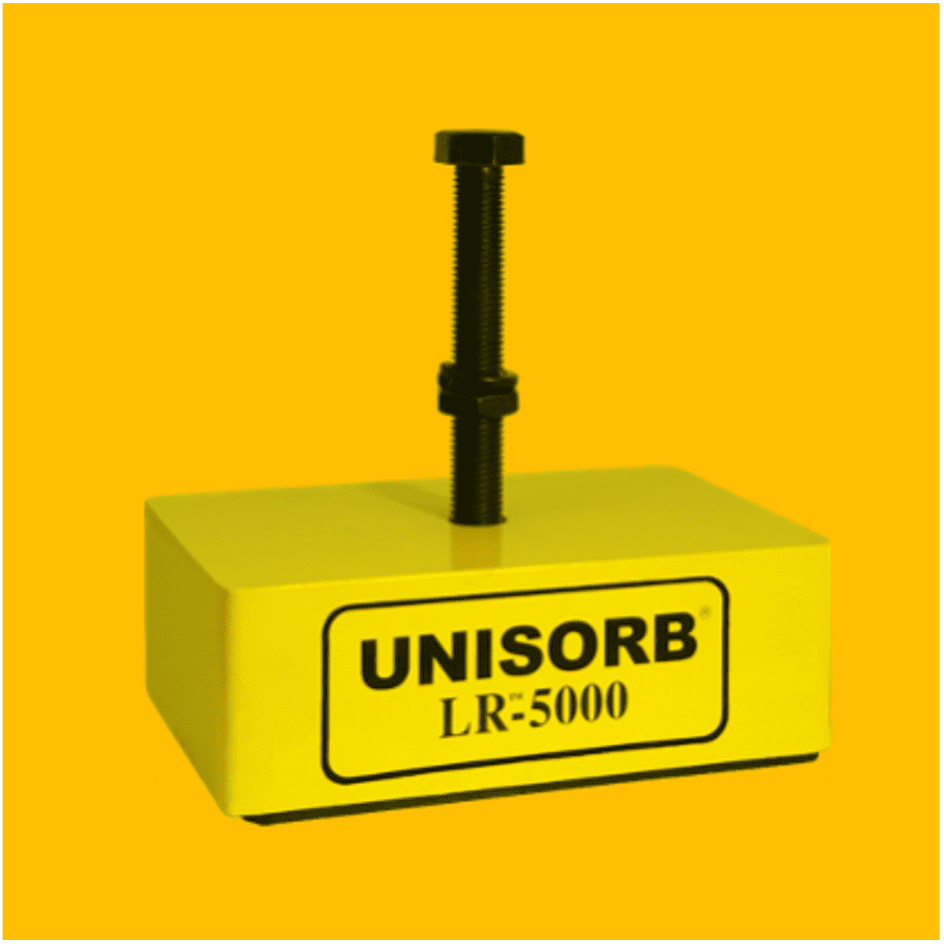

LR Machinery Mounts

(9 different sizes)

Precision-engineered ductile-iron mounts with a 1-3/8-inch adjustment range, proprietary elastomer isolation, and a stable rectangular design that delivers accurate leveling and superior vibration control on uneven floors. (Available in nine sizes.)

R-Series Machinery Mounts

(6 sizes)

Self-contained mounts with 1/2-inch elastomeric pads, rugged cast iron and black oxide steel, and a free-floating leveling screw that offers up to a 2-inch vertical adjustment while compensating for uneven floors. (Available in six sizes).

U-Series Machinery Mounts

(6 sizes)

Self-contained mounts with elastomeric pads designed to accept machinery leveling screws, offering rugged, heavy-duty construction for precision and finishing equipment. Does not include leveling accessories. (Available in six sizes.)

UNISORB in Action

A leading manufacturer recently resolved persistent machine tool alignment and vibration challenges using our RK Fixators and Standard V-100 Epoxy Grout solutions. Their machine tool now operates smoother and more accurately than ever.