Foundation Isolation Solutions

Stable Foundations.

Precision Performance.

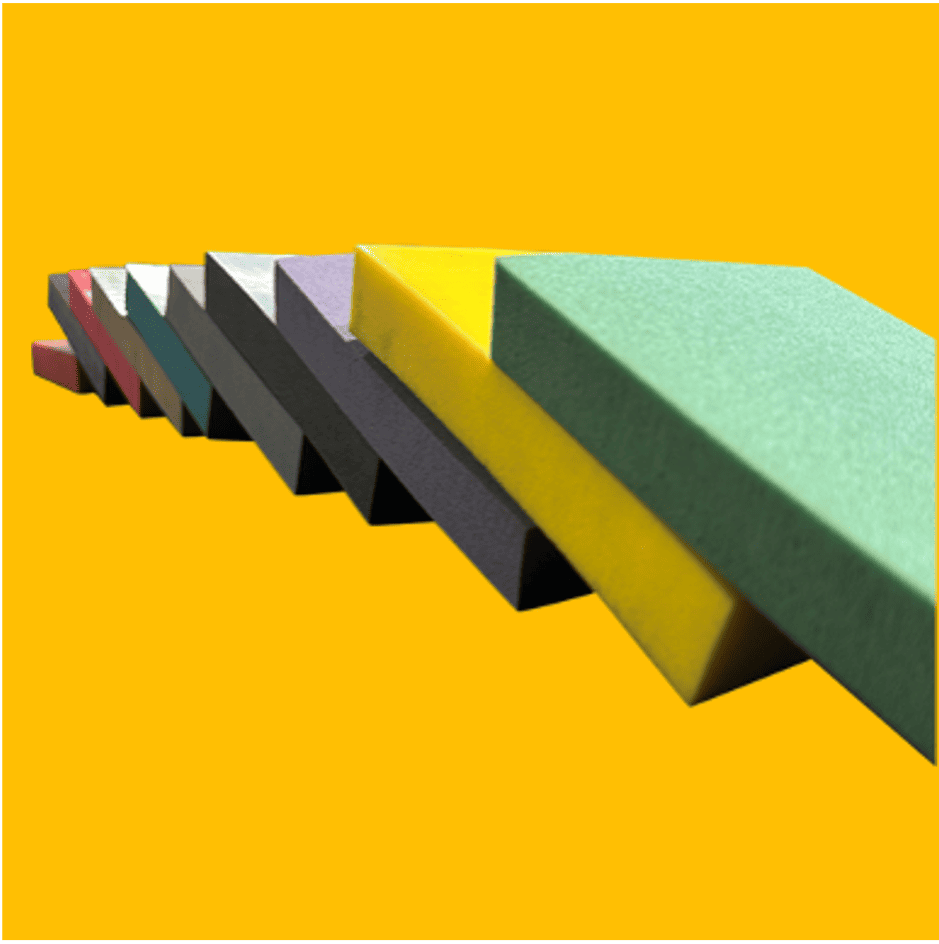

When it comes to support-critical machinery, foundation matters. UNISORB® Foundation Isolation Solutions are engineered to absorb vibration, eliminate shock, and maintain alignment, no matter how sensitive the equipment or demanding the environment. We make it simple to create stable, long-lasting foundations that keep your machines accurate, efficient, and happy.

Happy Machines.

Happy Customers.

"We had ongoing vibration issues affecting the accuracy of our testing equipment. After installing UNISORB’s Foundation Isolation System, we saw a dramatic improvement in stability and productivity."

– Facilities Engineer, Aerospace Industry

UNISORB in Action

A national medical device manufacturer was struggling to maintain calibration in sensitive lab equipment due to vibration from nearby rail traffic. By implementing UNISORB’s Regufoam VibrationPlus and RT-6.5 Low Frequency Isolation Blocks, they achieved a 90% reduction in vibration transfer, leading to more accurate test results, less recalibration, and a 25% boost in operational efficiency.

Our Services

When Your Machines Are Happy, Your Business is Too.