Grouting Solutions

Built to Hold.

Engineered to Last.

UNISORB® Grouting Solutions are the key to unlocking peak machine performance and unmatched longevity. Our grouts provide a solid machine-to-foundation connection to increase machine accuracy, ensure perfect alignment, and dramatically boost reliability – extending equipment life!

Happy Machines.

Happy Customers.

"With UNISORB’s world-class grouting solutions, we’ve experienced a significant improvement in our equipment's stability and performance. The machine-to-foundation connection has eliminated shifting and vibration issues, boosting accuracy and significantly extending the life of our machinery significantly."

– Maintenance Manager, Manufacturing Industry

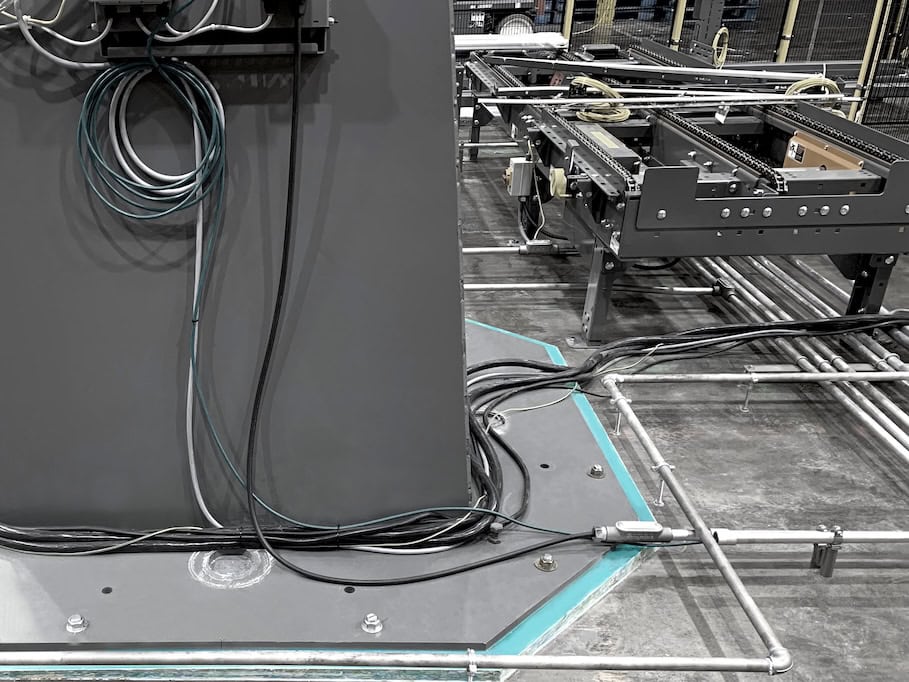

UNISORB in Action

At a major manufacturing plant, UNISORB grout was used to secure heavy machinery that had been experiencing frequent misalignment and excessive vibrations. After applying our epoxy grout, the equipment's stability dramatically improved, increasing machine accuracy and preventing costly malfunctions. As a result, the plant saw a 30% increase in machine efficiency and a significant reduction in maintenance downtime.

Our Services

When Your Machines Are Happy, Your Business is Too.